Project management methods have evolved for centuries, from records at the Pyramid at Giza to rebuilding London churches after the Great Fire of London in 1666, to the Great Western Railway.

The best-known modern methods of managing projects efficiently are:

- The Gantt chart developed by Henry Gantt in the 1910s

- Critical Path invented in the 1950s

- PERT method invented in 1958

- Critical Chain Method invented in 1997

But none of these methods are fool-proof. We often still over estimate the project timeline. Why does this happen?

What is the “planning fallacy”?

Critical Chain uses common sense considerations that are ignored in most other methods. Foremost among them is the concept of variation. Tasks in other tools can only be estimated in a static value considered an average. This methodology disregards the fact that many tasks vary in length of effort to complete, as anyone who deals with projects can attest to. Which often results in underestimating the time it takes to complete each task.

The planning fallacy happens to the best of us. The term was first coined in 1977 by psychologists Daniel Kahneman and Amos Tversky. In Kahneman’s book, Thinking Fast and Slow he suggests that estimation miscalculations are usually due to:

- A tendency to minimize historical data when estimating how long it will take to complete tasks

- Assuming that there won’t be any complications that will cause delays

Not incorporating uncertainty mixed with overconfidence in ourselves (or just pure optimism) leads to unrealistic estimates and timelines when using static estimates.

The other factor often overlooked in project planning is the complex interconnectedness of dependencies in project planning. You may be the planner who already includes ‘padding’ into your project timeline. But you also need to align those tasks when each individual has availability in conjunction with their other priorities. Often teams make this mistake by thinking “it’s early – we’ll make it up later.” But that logic doesn’t always work when you have multiple dependencies between project teams.

Finally, consider the effect of providing an average time estimate on a project or task. This methodology ensures you will deliver your project or task on time only half of the time. This level of on-time delivery happens all too often, and it’s completely avoidable when incorporating ranged estimation.

What is Critical Chain Project Management?

The Critical Chain Project Management (CCPM) concept allows us to say goodbye to the planning fallacy by helping reduce inherent uncertainty and incorporate a ranged estimation to guarantee a more accurate on-time delivery. For those unfamiliar with Critical Chain, let’s start with BASIC methods:

- Create Project Diagram

- Gather task efforts, knowing that there are higher points

- Take a % of the time of the task or the project and create tracking buffer sizes

- Some of the time is discarded

- Take the longest path, with resource contention determined, and declare the Critical Chain, with the time buffer at the end.

- Since the time buffer is “too small,” the time buffer should be consumed as the project advances.

Sound daunting? Instead, use project management software to do this heavy lifting.

How LiquidPlanner Delivers a Critical Chain Project Plan

Both LiquidPlanner’s CLASSIC and NEW products do critical chain, as this their scheduling engine was built to account for this. In LiquidPlanner CLASSIC, there is a Critical Path highlighting feature, and we can see the project’s history and percent completion. It’s simple, and we can see that the project is yellow and, thus, in a warning state. The red bars indicate the tasks inside each projected to be completed after the target finish date. This methodology makes it easy to see what tasks need attention in order for a project to be completed on time.

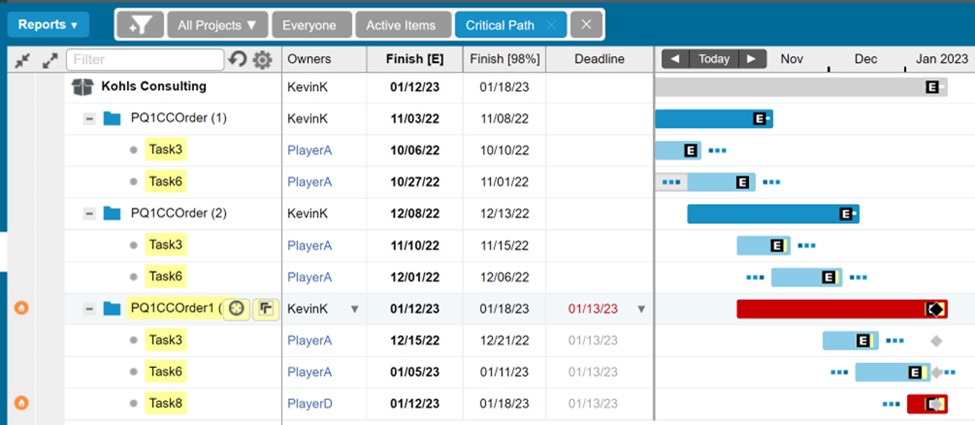

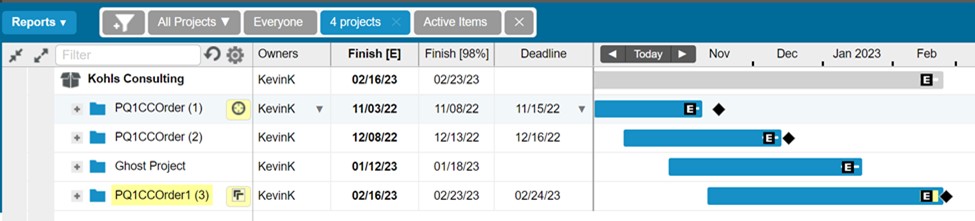

In this example, we are looking at the Critical Chain for PQ1CCOrder1 (3). There are several things here to note.

- The buffer is from Finish [E], which is the 50% on-time completion mark to 98%.

- This chart answers management’s questions – when will it be done? Our PQ1CCOrder1 (3) project will be finished with 50% confidence by 1/12, but the deadline is 1/13.

- The typical response: “It’s 9/22; we have plenty of time. We’ll work harder later on if needed.”

- This is where so many project leaders get it wrong – waiting to solve a “fatal” problem that we know exists now will only make our project more chaotic and less likely to be delivered on time. Let’s see if fixing a task on the critical chain makes a difference.

To fix this, all we had to do was look at what resource was not overbooked then and assign that task to that resource by leveraging built-in Workload views. This simple change likely saved us from delivering the project late or creating last minute chaos to scramble to get things accomplished in time. Here, Task3 in PQ1CCOrder1 (1) was reassigned to PlayerD, and we are now very confident that this project will finish on time.

We can see in LiquidPlanner the resources and tasks in this Critical Chain tasks. Resource PlayerA appears on every task, including two projects before PQ1CCOrder1 (3). Hence, improving Task3 in PQ1CCOrder1 (1) will also help PQ1CCOrder1 (3) because it is on the CC.

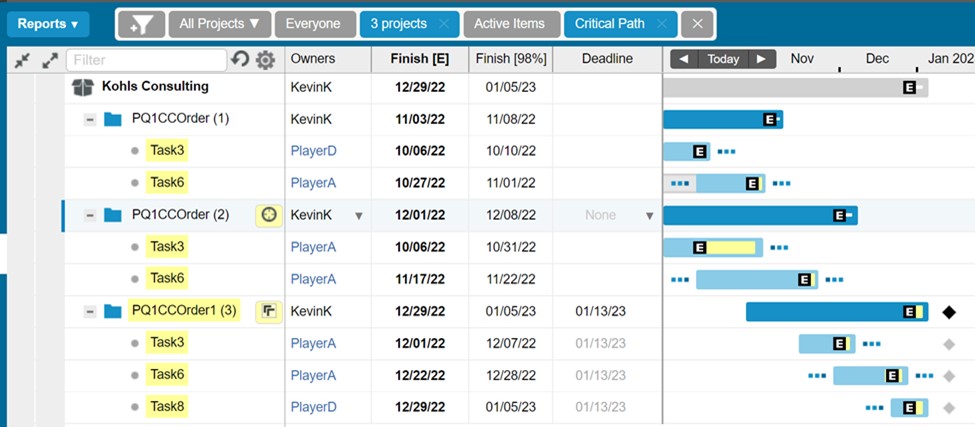

The flexibility of LiquidPlanner allows us to also scenario plan adding in another project. In the screenshot below we added a “ghost” project to understand if we have the flexibility to add high-priority projects at a premium. This is a common technique for suppliers who can rely on poor planning of their customers. Below we add a Ghost Project before PQ1CCOrder1 (3). Perhaps another company, because of their poor planning, asks for an emergency order. We agree to “fit it in” for a higher price. We have made incremental revenue by using our accurate CCPM methodology using LiquidPlanner. Profits have increased without any changes to our scheduling process or an increase in overtime.

Variability and change are the only things we can rely on in the business climate. Estimating task effort in ranges and leveraging CCPM methods to calculate the longest path with resource contention factored in allows you to break free of the planning fallacy and it highlights reality and risk so that mitigation can occur before it is too late. Don’t rely on any notion that we can “make up time later.”

Other tools in the Project Management space add to chaos and confusion. LiquidPlanner, on the other hand, can help you take advantage of constant change and uncertainty to gain control and improve your vision over the horizon. Their methodology allows you to increase On-Time Performance, accept new work without overworking employees, and increase your profits.

About the Author

Kevin Kohls is the leading authority in using the Theory of Constraints in the Auto Industry. He used LiquidPlanner successfully for engineering to order at Rex Materials to increase OTP by more than 95%. Kevin is also the author of Addicted to Hopium a book about the process of throughput and breaking the habit of guesswork. He can be contacted at kevin.kohls@yahoo.com. View Kevin’s LinkedIn here.

Kevin Kohls is the leading authority in using the Theory of Constraints in the Auto Industry. He used LiquidPlanner successfully for engineering to order at Rex Materials to increase OTP by more than 95%. Kevin is also the author of Addicted to Hopium a book about the process of throughput and breaking the habit of guesswork. He can be contacted at kevin.kohls@yahoo.com. View Kevin’s LinkedIn here.