While it can mostly be forecasted, the weather has its share of unpredictability, making many wish it could be managed like a project. One company based in Albuquerque, New Mexico, however, has been using LiquidPlanner to do just that.

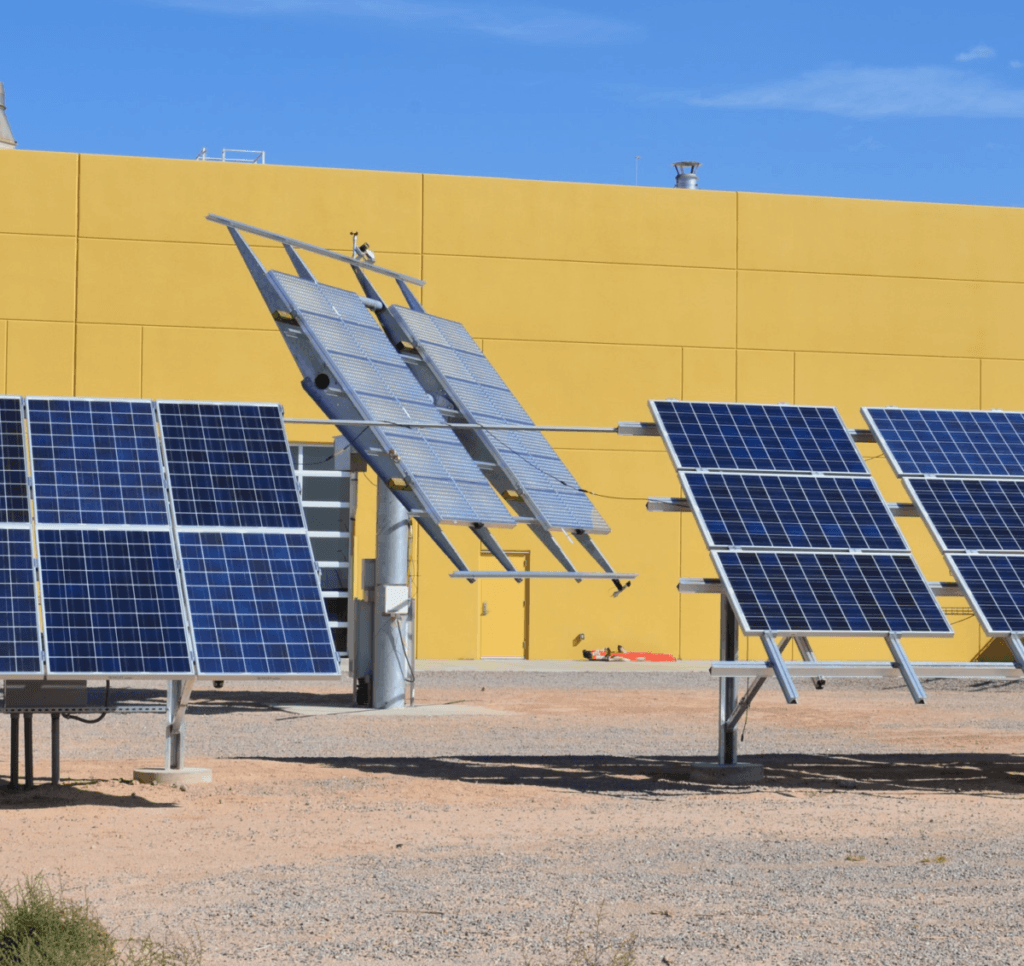

CFV Solar Test Laboratory, Inc., is a small, accredited, highly sophisticated laboratory that performs multistep, long-term, testing and certification of photovoltaic assemblies, using the latest equipment. “The nature of our business is such that our projects can be complicated, last months, and have complex dependencies,” says operations manager Chase Henson.

However, one of the most important steps in the photovoltaic certification process isn’t especially complicated, and it doesn’t require state-of-the-art equipment. Quite the opposite; to get information on the performance and longevity of a PV assembly in actual conditions, CFV engineers will usually do something as simple as leaving it outside for weeks or months at a time.

As simple as it is, outdoor testing is hard to do well, but it is important. The data gathered while the assembly is exposed to the elements is critical for several purposes that include the following:

- Performance and power yield studies, to predict long term performance.

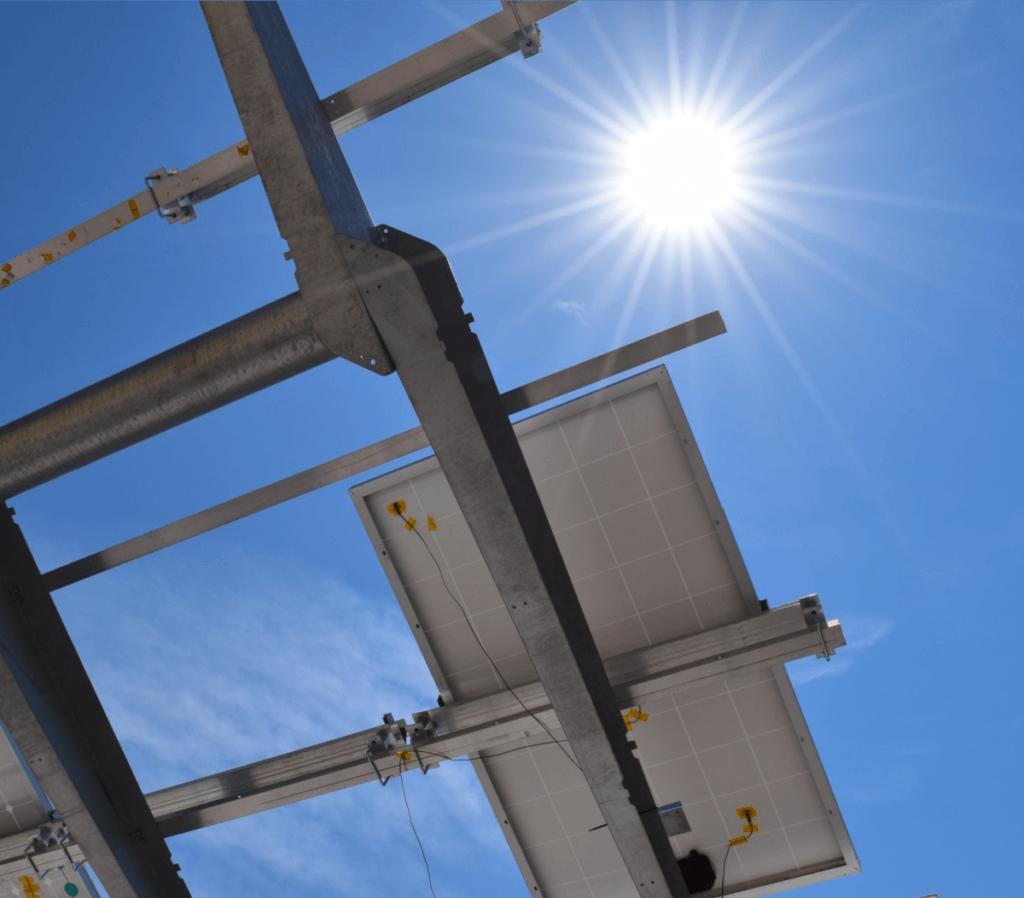

- Angle-of-incidence testing, a measure of photovoltaic response to sunlight hitting the assembly at different angles during the course of a day.

- Hot-spot, NOCT, and temperature-coefficient testing. “Hot spots” in PV panels are a result of underperformance of individual PV cells that increases the load on remaining cells; this underperformance can be caused by, for example, intermittent shade at certain times of the day. Temp-coefficient and nominal operating cell temperature (NOCT) are measures of the typical performance and temperature achieved by working cells in a PV module or assembly. These metrics are critical when bringing a PV product to market and determining them requires physical measurement of many variations of solar irradiance, air temperature, and wind velocity.

- Testing the real-world performance and durability of building-integrated photovoltaics (BIPV)—think roofing tiles, skylights, and other construction materials that incorporate PV cells—and PV assemblies intended for rooftop mounting.

To perform all these tests accurately, the assemblies need to be exposed to sufficient quantities of particular kinds of weather, such as a month of sunny days or one good hailstorm. For CFV, the outdoors is considered an important piece of lab equipment. Unfortunately, the outdoors can be unsatisfactory because it’s so unpredictable; even in New Mexico, PV assemblies may not be exposed to enough continuous sunshine to gather the data needed within project timeframes, and hail or high humidity may not happen at all for months at a time.

That’s where good project management comes in; in CFV’s implementation of LiquidPlanner, ‘outside’ is considered a resource, and LiquidPlanner’s industry-leading predictive scheduling engine can be used to track the performance of this resource.

Of course, when Mother Nature doesn’t perform as desired there’s not much to be done about it; after all, managers can’t push for more sunny days, or a little rain, just because a project is falling behind schedule. A manager can, however, track the amount of particular weather conditions a PV module is being exposed to, update that resource utilization as needed, and use LiquidPlanner’s predictive scheduling engine to forecast project completion dates.

If forecasts aren’t good (pun totally intended), CFV does have options. The lab is one of the only North American certification facilities that operates its own damp heat and climate chambers to simulate multiple weather conditions, including hail, and fast climate chambers that can simulate long exposure to varying seasonal weather by rapidly cycling between temperature extremes from 35ºC (95ºF) to -240ºC (-400ºF).

Time in climate chambers is expensive because PV modules can be large and chamber space is limited; chambers are treated as a valuable resource, and chamber hours are tracked carefully. Exposure to the elements is also tracked as a resource, so when the weather isn’t cooperating, CFV managers can adjust the use of chambers and the outdoors as needed to keep projects on schedule and within budget. The ability to quickly visualize the results of trading off as needed between these two resources has been a major workflow victory, and an important factor in making CFV Solar the fastest and most reliable photovoltaic certification laboratory in North America.

That’s how you manage weather with LiquidPlanner.

Want to learn more about CFV Solar Testing Laboratory? Read the customer story!